Abstract

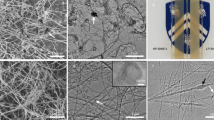

Boron nitride nanotubes (BNNTs) possess extraordinary properties on the molecular level; hence, it is of particular interest to use them for the assembly of macroscopic materials. However, difficulties in BNNT synthesis and purification hinder their processing into such objects. Only recently, a large-scale production of high-quality BNNTs has been explored. Here, we study by advanced electron microscopy techniques BNNTs synthesized by the high temperature–pressure (HTP) method and compare BNNTs after different purification processes. We document many different defects and demonstrate that these do not prevent nematic alignment of BNNTs at high concentrations. In fact, we show that small-ordered domains form at lower concentrations for BNNTs of higher purity. Cryogenic electron microscopy provides direct-imaging evidence of the BNNT liquid crystalline phase, indicating the potential for the fabrication of highly ordered BNNT-based macroscopic assemblies by liquid-phase processing.

Graphical abstract

Similar content being viewed by others

Data availability

The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

I. Sumio, Helical microtubules of graphitic carbon. Nature 353, 412–414 (1991). https://doi.org/10.1038/354056a0

N.G. Chopra, R.J. Luyken, K. Cherrey, V.H. Crespi, M.L. Cohen, S.G. Louie, A. Zettl, Boron nitride nanotubes. Science 269, 966–967 (1995). https://doi.org/10.1126/science.269.5226.966

G. Ciofani, V. Mattoli, Boron Nitride Nanotubes in Nanomedicine, 1st edn. (Elsevier, Oxford, 2016)

A.W. Thornton, A. Ahmed, M. Mainak, H.B. Park, A.J. Hill, Functionalization and applications of boron nitride and other nanomaterials, in Nanotubes and Nanosheets. (CRC Press, Boca Raton, 2015), pp.271–304. https://doi.org/10.1201/b18073

N.G. Chopra, A. Zettl, Measurement of the elastic modulus of a multi-wall boron nitride nanotube. Solid State Commun. 105, 297–300 (1998). https://doi.org/10.1016/S0038-1098(97)10125-9

A. Rubio, J.L. Corkill, M.L. Cohen, Theory of graphitic boron nitride nanotubes. Phys. Rev. B 49, 5081–5084 (1994). https://doi.org/10.1103/PhysRevB.49.5081

X. Blase, A. Rubio, S.G. Louie, M.L. Cohen, Stability and band gap constancy of boron nitride nanotubes. EPL 28, 335–340 (1994). https://doi.org/10.1209/0295-5075/28/5/007

Y. Chen, J. Zou, S.J. Campbell, G. Le Caer, Boron nitride nanotubes: pronounced resistance to oxidation. Appl. Phys. Lett. 84, 2430–2432 (2004). https://doi.org/10.1063/1.1667278

C. Zhi, Y. Bando, C. Tang, D. Golberg, Boron nitride nanotubes. Mater. Sci. Eng. R Rep. 70, 92–111 (2010). https://doi.org/10.1016/j.mser.2010.06.004

D. Golberg, Y. Bando, Unique morphologies of boron nitride nanotubes. Appl. Phys. Lett. 79, 415–417 (2001). https://doi.org/10.1063/1.1385188

M.W. Smith, K.C. Jordan, C. Park, J.W. Kim, P.T. Lillehei, R. Crooks, J.S. Harrison, Very long single-and few-walled boron nitride nanotubes via the pressurized vapor/condenser method. Nanotechnology (2009). https://doi.org/10.1088/0957-4484/20/50/505604

A.L. Tiano, C. Park, J.W. Lee, H.H. Luong, L.J. Gibbons, S.-H. Chu, S. Applin, P. Gnoffo, S. Lowther, H.J. Kim, P.M. Danehy, J.A. Inman, S.B. Jones, J.H. Kang, G. Sauti, S.A. Thibeault, V. Yamakov, K.E. Wise, J. Su, C.C. Fay, Boron nitride nanotube: synthesis and applications, Proc. SPIE 9060, Nanosensors, Biosensors, Info-Tech Sensors Syst. 906006 (2014). https://doi.org/10.1117/12.2045396

K. Keun Su, K. Myung Jong, P. Cheol, C.F. Catharine, C. Sang-Hyon, T.K. Christopher, S. Benoit, Scalable manufacturing of boron nitride nanotubes and their assemblies: a review. Semicond. Sci. Technol. 32, 13003 (2017)

K.S. Kim, C.T. Kingston, A. Hrdina, M.B. Jakubinek, J. Guan, M. Plunkett, B. Simard, Hydrogen-catalyzed, pilot-scale production of small-diameter boron nitride nanotubes and their macroscopic assemblies. ACS Nano 8, 6211–6220 (2014). https://doi.org/10.1021/nn501661p

O. Kleinerman, M. Adnan, D.M. Marincel, A.W.K. Ma, E.A. Bengio, C. Park, S.H. Chu, M. Pasquali, Y. Talmon, Dissolution and characterization of boron nitride nanotubes in superacid. Langmuir 33, 14340–14346 (2017). https://doi.org/10.1021/acs.langmuir.7b03461

D.M. Marincel, M. Adnan, J. Ma, E.A. Bengio, M.A. Trafford, O. Kleinerman, D.V. Kosynkin, S.H. Chu, C. Park, S.J.A. Hocker, C.C. Fay, S. Arepalli, A.A. Martí, Y. Talmon, M. Pasquali, Scalable purification of boron nitride nanotubes via wet thermal etching. Chem. Mater. 31, 1520–1527 (2019). https://doi.org/10.1021/acs.chemmater.8b03785

M. Adnan, D.M. Marincel, O. Kleinerman, S.H. Chu, C. Park, S.J.A. Hocker, C. Fay, S. Arepalli, Y. Talmon, M. Pasquali, Extraction of boron nitride nanotubes and fabrication of macroscopic articles using chlorosulfonic acid. Nano Lett. 18, 1615–1619 (2018). https://doi.org/10.1021/acs.nanolett.7b04335

C.J.S. Ginestra, C. Martínez-jiménez, A. Matayaho Ya’akobi, O.S. Dewey, A.D. Smith McWilliams, R.J. Headrick, J.A. Acapulco, L.R. Scammell, M.W. Smith, D.V. Kosynkin, D.M. Marincel, C. Park, S.-H. Chu, Y. Talmon, A. Marti, M. Pasquali, Liquid crystals of neat boron nitride nanotubes and their assembly into ordered macroscopic materials. Nat. Commun. 13, 3136 (2022). https://doi.org/10.1038/s41467-022-30378-5

H. Cho, S. Walker, M. Plunkett, D. Ruth, R. Iannitto, Y. Martinez Rubi, K.S. Kim, C.M. Homenick, A. Brinkmann, M. Couillard, S. Dénommée, J. Guan, M.B. Jakubinek, Z.J. Jakubek, C.T. Kingston, B. Simard, Scalable gas-phase purification of boron nitride nanotubes by selective chlorine etching. Chem. Mater. (2020). https://doi.org/10.1021/acs.chemmater.0c00144

S.H. Lee, M. Kang, H. Lim, S.Y. Moon, M.J. Kim, S.G. Jang, H.J. Lee, H. Cho, S. Ahn, Purification of boron nitride nanotubes by functionalization and removal of poly(4-vinylpyridine). Appl. Surf. Sci. 555, 149722 (2021). https://doi.org/10.1016/j.apsusc.2021.149722

V.R. Kode, M.E. Thompson, C. McDonald, J. Weicherding, T.D. Dobrila, P.S. Fodor, C.L. Wirth, G. Ao, Purification and assembly of DNA-stabilized boron nitride nanotubes into aligned films. ACS Appl. Nano Mater. 2, 2099–2105 (2019). https://doi.org/10.1021/acsanm.9b00088

M.S. Amin, B. Atwater, R.D. Pike, K.E. Williamson, D.E. Kranbuehl, H.C. Schniepp, High-purity boron nitride nanotubes via high-yield hydrocarbon solvent processing. Chem. Mater. 31, 8351–8357 (2019). https://doi.org/10.1021/acs.chemmater.9b01713

T. Oku, Synthesis, Atomic Structures and Properties of Boron Nitride Nanotubes (Intech Open, London, 2013)

A. Klug, From virus structure to Chromatin: X-ray diffraction to three-dimensional electron microscopy. Annu. Rev. Biochem. 79, 1–35 (2010). https://doi.org/10.1146/annurev.biochem.79.091407.093947

O. Kleinerman, A.N.G. Parra-Vasquez, M.J. Green, N. Behabtu, J. Schmidt, E. Kesselman, C.C. Young, Y. Cohen, M. Pasquali, Y. Talmon, Cryogenic-temperature electron microscopy direct imaging of carbon nanotubes and graphene solutions in superacids. J. Microsc. 259, 16–25 (2015). https://doi.org/10.1111/jmi.12243

D.E. Tsentalovich, R.J. Headrick, F. Mirri, J. Hao, N. Behabtu, C.C. Young, M. Pasquali, Influence of carbon nanotube characteristics on macroscopic fiber properties. ACS Appl. Mater. Interfaces 9, 36189–36198 (2017). https://doi.org/10.1021/acsami.7b10968

D. Golberg, Y. Bando, L. Bourgeois, K. Kurashima, T. Sato, Insights into the structure of BN nanotubes. Appl. Phys. Lett. 77, 1979–1981 (2000). https://doi.org/10.1063/1.1313251

Z.L. Wang, C. Hui, Electron Microscopy of Nanotubes (Springer, New York, 2003)

M.J. Green, C.C. Young, A.N.G. Parra-Vasquez, M. Majumder, V. Juloori, N. Behabtu, C.L. Pint, J. Schmidt, E. Kesselman, R.H. Hauge, Y. Cohen, Y. Talmon, M. Pasquali, Direct imaging of carbon nanotubes spontaneously filled with solvent. Chem. Commun. 47, 1228–1230 (2011). https://doi.org/10.1039/c0cc03915b

J.R. Bellare, H.T. Davis, L.E. Scriven, Y. Talmon, Controlled environment vitrification system: an improved sample preparation technique. J. Electron Microsc. Tech. 10, 87–111 (1988). https://doi.org/10.1002/jemt.1060100111

L. Liberman, O. Kleinerman, I. Davidovich, Y. Talmon, Micrograph contrast in low-voltage SEM and cryo-SEM. Ultramicroscopy 218, 113085 (2020). https://doi.org/10.1016/j.ultramic.2020.113085

L. Issman, Y. Talmon, Cryo-SEM specimen preparation under controlled temperature and concentration conditions. J. Microsc. 246, 60–69 (2012). https://doi.org/10.1111/j.1365-2818.2011.03587.x

Acknowledgments

Our research was supported by Air Force Office of Scientific Research (AFOSR) Grants FA9550-18-1-0014 and FA9550-19-1-7045, and the United States−Israel Binational Science Foundation Grant 2016161. MP’s work was supported by The Robert A. Welch Foundation grant C-1668. Cryo-EM was performed at the Technion Center for Electron Microscopy of Soft Matter supported by the Technion Russell Berrie Nanotechnology Institute (RBNI).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors Scammell and Smith are employees of BNNT Materials LLC, and author Smith is a shareholder in BNNT Materials LLC. The remaining authors declare that they have no conflict of interest.

Additional information

Matteo Pasquali was a guest editor of this journal during the review and decision stage. For the JMR policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/editor-manuscripts/.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Matatyaho Ya’akobi, A., Ginestra, C.J.S., Scammell, L.R. et al. Electron microscopy study of BNNTs synthesized by high temperature–pressure method and purified by high-temperature steam. Journal of Materials Research 37, 4508–4521 (2022). https://doi.org/10.1557/s43578-022-00697-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00697-w